Affordable, scalable protein production and kinetics

New drug development, synthetic biology, plasma proteomics and diagnostics all share a common requirement: the need to produce and test thousands of protein.

Affordable, scalable protein production and kinetics

New drug development, synthetic biology, plasma proteomics and diagnostics all share a common requirement: the need to produce and test thousands of protein.

We developed the SPOC platform to address two major challenges in biology: affordable, scalable protein production and direct measurement of protein binding kinetics.

We developed the SPOC platform to address two major challenges in biology: affordable, scalable protein production and direct measurement of protein binding kinetics.

High-Volume Protein Production

High-Volume Protein Production

SPOC enables simultaneous cell free production and capture-purification of 384 up to 1,000 unique proteins directly onto a 1.5 sq-cm gold coated biosensor chip for kinetic analysis using surface plasmon resonance (SPR) biosensing.

We have demonstrated capability to produce SPOC biosensor chips with up to 2,400 proteins on a single chip.

SPOC MALDI Mass Spec compatibility is in development to enable production and screening of >10,000 proteins at once.

SPOC enables simultaneous cell free production and capture-purification of 384 up to 1,000 unique proteins directly onto a 1.5 sq-cm gold coated biosensor chip for kinetic analysis using surface plasmon resonance (SPR) biosensing.

We have demonstrated capability to produce SPOC biosensor chips with up to 2,400 proteins on a single chip.

SPOC MALDI Mass Spec compatibility is in development to enable production and screening of >10,000 proteins at once.

While we offer in-house screening services in select cases, SPOC Proteomics will produce and ship catalog and custom SPOC chips to users to facilitate study of protein function at scale.

While we offer in-house screening services in select cases, SPOC Proteomics will produce and ship catalog and custom SPOC chips to users to facilitate study of protein function at scale.

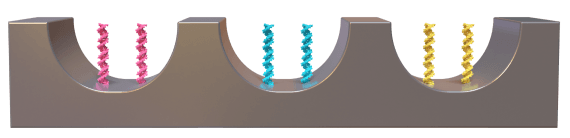

Protein Nano Factory

Single step protein expression and capture-purification in nanowells.

01

Plasmid DNA is printed into nanowells.

Plasmid DNA encoding proteins of interest are printed in nano-liter volume wells, on a nanowell slide comprising tens of thousands of wells.

02

Wells are filled with cell lysate, containing the enzymes for transcription and translation.

Human cell lysate is used to ensure native folding proper functionality and post-translational modifications (PTMs) of human protein targets. E.coli lysate (and CHO in future) is used to produce other proteins.

03

Full length folded proteins are produced in each nanowell.

Biosensor chips are coated with capture agent that forms covalent bond with the common fusion tag expressed in all the nanowells

04

Pure protein spots covalently captured on biosensor chip

Protein expressed in the nanowells are directly capture-purified onto the biosensor surface, to produce pure protein spots on the biosensor chips. Protein production and capture in sealed wells ensures no discernable cross-binding at neighboring spots.

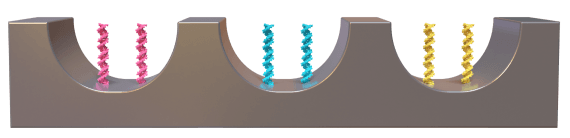

Protein Nano Factory

Single step protein expression and capture-purification in nanowells.

01

Plasmid DNA is printed into nanowells.

Plasmid DNA encoding proteins of interest are printed in nano-liter volume wells, on a nanowell slide comprising tens of thousands of wells.

02

Wells are filled with cell lysate, containing the enzymes for transcription and translation.

Human cell lysate is used to ensure native folding proper functionality and post-translational modifications (PTMs) of human protein targets. E.coli lysate (and CHO in future) is used to produce other proteins.

03

Full length folded proteins are produced in each nanowell.

Biosensor chips are coated with capture agent that forms covalent bond with the common fusion tag expressed in all the nanowells

04

Pure protein spots covalently captured on biosensor chip

Protein expressed in the nanowells are directly capture-purified onto the biosensor surface, to produce pure protein spots on the biosensor chips. Protein production and capture in sealed wells ensures no discernable cross-binding at neighboring spots.

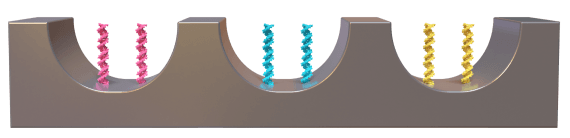

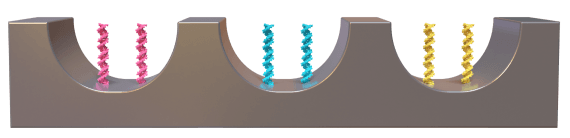

Protein Nano Factory

Single step protein expression and capture-purification in nanowells.

01

Plasmid DNA is printed into nanowells.

Plasmid DNA encoding proteins of interest are printed in nano-liter volume wells, on a nanowell slide comprising tens of thousands of wells.

02

Wells are filled with cell lysate, containing the enzymes for transcription and translation.

Human cell lysate is used to ensure native folding proper functionality and post-translational modifications (PTMs) of human protein targets. E.coli lysate (and CHO in future) is used to produce other proteins.

03

Full length folded proteins are produced in each nanowell.

Biosensor chips are coated with capture agent that forms covalent bond with the common fusion tag expressed in all the nanowells

04

Pure protein spots covalently captured on biosensor chip

Protein expressed in the nanowells are directly capture-purified onto the biosensor surface, to produce pure protein spots on the biosensor chips. Protein production and capture in sealed wells ensures no discernable cross-binding at neighboring spots.

SPOC’s Protein Capabilities

SPOC’s Protein Capabilities

Currently, our database include DNA (plasmids) to produce 10,000+ human proteins and 5,000+ pathogen proteins. SPOC protein chips are stored at -20C (tested for no loss in function) or shipped to users.

In future, SPOC Biosciences will expand product offerings to mass spectroscopy screening using MALDI TOF and TimsTOF. Large scanning area of MALDI sensor surfaces enables

production and screening of 10,000 – 30,000 proteins in a single assay. Screening with drug libraries such as DELs, biologics, SPOC MALDI mass spec screening will output 1 – 10 million data points on drug-protein bindings.

Currently, our database include DNA (plasmids) to produce 10,000+ human proteins and 5,000+ pathogen proteins. SPOC protein chips are stored at -20C (tested for no loss in function) or shipped to users.

In future, SPOC Biosciences will expand product offerings to mass spectroscopy screening using MALDI TOF and TimsTOF. Large scanning area of MALDI sensor surfaces enables

production and screening of 10,000 – 30,000 proteins in a single assay. Screening with drug libraries such as DELs, biologics, SPOC MALDI mass spec screening will output 1 – 10 million data points on drug-protein bindings.

SPR Chip and Kinetics

SPR Chip and Kinetics

Simultaneous HTS of Sensor

SPOC chips enable simultaneous analysis of thousands of proteins on SPR biosensing instruments. By injecting a sample (analyte), binding interactions are measured, providing comprehensive qualitative, quantitative, and kinetic data.

SPOC chips enable simultaneous analysis of thousands of proteins on SPR biosensing instruments. By injecting a sample (analyte), binding interactions are measured, providing comprehensive qualitative, quantitative, and kinetic data.

SPOC facilitates simultaneous measurement of key kinetic parameters—rate of association (ka), rate of dissociation (kd), kinetic affinity (KD), and residence half-life (t1/2)—for all protein interactions on the SPR biosensor chip.

SPOC facilitates simultaneous measurement of key kinetic parameters—rate of association (ka), rate of dissociation (kd), kinetic affinity (KD), and residence half-life (t1/2)—for all protein interactions on the SPR biosensor chip.

SPOC has validated kinetic analysis of 384 proteins with Carterra’s custom SPR instrument and Horiba’s Openplex. Upcoming developments include software for screening 1,000 to 2,400 proteins and compatibility with more SPR instruments.

SPOC has validated kinetic analysis of 384 proteins with Carterra’s custom SPR instrument and Horiba’s Openplex. Upcoming developments include software for screening 1,000 to 2,400 proteins and compatibility with more SPR instruments.

Simultaneous HTS of Sensor

Each sensorgram = Data from unique spot

Each sensorgram = Data from unique spot

133 nM

133 nM

66.5 nM

66.5 nM

33.3 nM

33.3 nM

16.6 nM

16.6 nM

8.31 nM

8.31 nM

SPOC Biosciences’ goal is to enable compatibility with a broad range of SPR and MALDI mass spec instruments, to facilitate instrument agnostic screening of protein–protein and drug–protein interactions at scale.

SPOC Biosciences’ goal is to enable compatibility with a broad range of SPR and MALDI mass spec instruments, to facilitate instrument agnostic screening of protein–protein and drug–protein interactions at scale.

Our main advantages

Our main advantages

01

The challenges in studying proteins at scale

Producing or commercially sourcing purified recombinant proteins typically costs around $500 per protein, making large-scale studies involving thousands of proteins financially unfeasible. Our Protein Nano Factory overcomes this barrier by producing 100s to 1000s of proteins in a single capture-purification step, at a fraction of the cost.

02

High Costs and Labor of Kinetic Analysis

The current state-of-the-art in kinetic analysis relies on microfluidics to spot proteins or drug molecules onto SPR biosensor chips. However, when screening hundreds to thousands of drug-protein binding kinetics, this process becomes highly labor-intensive and costly. SPOC streamlines this by directly producing full-length, folded proteins or single-chain antibodies on biosensor chips, ready for immediate kinetic screening, significantly reducing time and expense.

03

Quality Assurance and Quality Control (QA & QC)

Proteins are expressed with fusion capture tag (an enzyme) on either N- or C- terminus, as desired. The fusion tag is itself an enzyme that reacts and forms covalent bond with ligand coated on biosensor chip, leading to protein capture. When capture tag is expressed last, on-chip capture confirms in-frame expression, as proper folding of tag-enzyme is needed for capture. Protein expression at each of the 1000 spots on the biosensor chip is validated using antibody that binds to this common enzyme-tag. Select control proteins are produced at multiple spots across the array, enabling assay with specific antibodies to verify reproducible expression levels. Further, enzymes and enzyme-substrates (control proteins) produced on SPOC chip are tested to verify enzymatic activity. For custom SPOC chips, we will incorporate customer-defined protein or assay specific validation steps and QA/QC metrics.

04

Limits of length of protein expressed

We do not see an inherent limit to the length of protein being expressed on our platform. Cell free systems are known to produce over 200 KDa proteins.

05

Producing membrane proteins

Currently, SPOC produces extracellular domains (ECDs) of membrane proteins on biosensor chips, which is ideal for binding studies and off-target screening. To expand the capabilities to functional studies, we plan to integrate membrane nanodisc technology to enable the production of full-length membrane proteins directly on the SPOC platform.

06

Studying post translational modifications (PTMs)

Native PTMs are known to occur in human cell free lysate. To ensure specific PTMs, enzymes and chaperone proteins are added to the cell lysate. Alternately, PTM modifying enzymes can be co-printed and co-expressed in specific nanowells. Further, all on-chip proteins can be assayed with enzymes to produce desired PTMs, or to discover new substrates of enzymes of interest.

07

Regeneration and multiple use of SPOC Chips

Proteins are captured on SPOC biosensor surfaces using covalent capture chemistry, enabling multiple cycles of regeneration and analyte screening, depending on the specific on-chip proteins being assayed.

The challenges in studying proteins at scale

Producing or commercially sourcing purified recombinant proteins typically costs around $500 per protein, making large-scale studies involving thousands of proteins financially unfeasible. Our Protein Nano Factory overcomes this barrier by producing 100s to 1000s of proteins in a single capture-purification step, at a fraction of the cost.

High Costs and Labor of Kinetic Analysis

The current state-of-the-art in kinetic analysis relies on microfluidics to spot proteins or drug molecules onto SPR biosensor chips. However, when screening hundreds to thousands of drug-protein binding kinetics, this process becomes highly labor-intensive and costly. SPOC streamlines this by directly producing full-length, folded proteins or single-chain antibodies on biosensor chips, ready for immediate kinetic screening, significantly reducing time and expense.

Quality Assurance and Quality Control (QA & QC)

Proteins are expressed with fusion capture tag (an enzyme) on either N- or C- terminus, as desired. The fusion tag is itself an enzyme that reacts and forms covalent bond with ligand coated on biosensor chip, leading to protein capture. When capture tag is expressed last, on-chip capture confirms in-frame expression, as proper folding of tag-enzyme is needed for capture. Protein expression at each of the 1000 spots on the biosensor chip is validated using antibody that binds to this common enzyme-tag. Select control proteins are produced at multiple spots across the array, enabling assay with specific antibodies to verify reproducible expression levels. Further, enzymes and enzyme-substrates (control proteins) produced on SPOC chip are tested to verify enzymatic activity. For custom SPOC chips, we will incorporate customer-defined protein or assay specific validation steps and QA/QC metrics.

Limits of length of protein expressed

We do not see an inherent limit to the length of protein being expressed on our platform. Cell free systems are known to produce over 200 KDa proteins.

Producing membrane proteins

Currently, SPOC produces extracellular domains (ECDs) of membrane proteins on biosensor chips, which is ideal for binding studies and off-target screening. To expand the capabilities to functional studies, we plan to integrate membrane nanodisc technology to enable the production of full-length membrane proteins directly on the SPOC platform.

Studying post translational modifications (PTMs)

Native PTMs are known to occur in human cell free lysate. To ensure specific PTMs, enzymes and chaperone proteins are added to the cell lysate. Alternately, PTM modifying enzymes can be co-printed and co-expressed in specific nanowells. Further, all on-chip proteins can be assayed with enzymes to produce desired PTMs, or to discover new substrates of enzymes of interest.

Regeneration and multiple use of SPOC Chips

Proteins are captured on SPOC biosensor surfaces using covalent capture chemistry, enabling multiple cycles of regeneration and analyte screening, depending on the specific on-chip proteins being assayed.

Join us in transforming healthcare through the power of proteomics

Join us in transforming healthcare through the power of proteomics

Publications

Publications

Novel sensor-integrated proteome on chip (SPOC) platform with thousands of folded proteins on a 1.5 sq-cm biosensor chip to enable high-throughput real-time label-free screening for kinetic analysis (Nature Communications Biology)

A customizable biosensor for label-free detection of in-solution analytes using highly multiplexed cell-free synthesis of single-chain antibodies (bioRxiv)

Product Brochure

Product Brochure

For more information on the SPOC platform, get in touch:

Contact Us

1600 Adams Drive

Suite 236

Menlo Park, CA 94025

7201 E Henkel Way

Suite 285

Scottsdale, AZ 85255

480-219-9506

For more information on the SPOC platform, get in touch:

Contact Us

1600 Adams Drive

Suite 236

Menlo Park, CA 94025

7201 E Henkel Way

Suite 285

Scottsdale, AZ 85255

480-219-9506

Privacy & Conditions

All rights reserved © 2024